Many food companies have done a good job of sterilization during food production and processing, but the problem of excessive microorganisms still occurs. After a series of investigations, the food factory finally found the source of secondary pollution. At the same time, hand disinfection and sterilization are not in place, because many domestic food companies still have traditional hand disinfection and sterilization methods such as basin washing. The disadvantage of this hand sterilization mode is that, Because many people are using the same disinfection and sterilization tool, the disinfection and sterilization effect of the disinfectant decreases after repeated use, and it cannot achieve the effect of sterilization and disinfection of the hands. And because many people have contact with disinfection and sterilization equipment, this may lead to cross-infection.

According to Chief Engineer Zhou of Shanghai Kangjiu Disinfection and Sterilization Technology, who specializes in the research and development of food processing and production sterilization technology and automatic hand sterilizers for employees, many reasons can cause the number of microorganisms in food processing to exceed the standard, and the microorganisms in the hands of workers in food workshops. Excessive numbers can be a major source of microbial contamination. The selection of NICOLER automatic induction hand sanitizer can effectively improve the hand hygiene of employees in the food workshop, eliminate the secondary contamination of food by hand microorganisms, and thus improve the hygiene, safety and quality of food.

Because in our daily life and work, our hands need to be in contact with various items, and some of these items may have more microorganisms, once these microorganisms adhere to human hands. Then, when touching other items, it will cause cross-infection. In order to maintain hand hygiene, we should wash our hands frequently, and those in the food processing industry should wash our hands frequently, and at the same time do a good job of sterilization and disinfection of our hands. Because the disinfection and sterilization process in the process of food processing is more standardized and stricter than our daily routine, if you simply wash your hands, it cannot meet the hygiene requirements in the food production process, and the unhygienic hands of production workers have Many microorganisms will contaminate food in different ways, causing food spoilage and shortening the shelf life of food, which will bring harm to food production and processing enterprises and consumers.

Food hygiene and safety is a systematic project involving many reasons. Some food companies ignore the importance of disinfection and sterilization of the hands of production workers. The hands of workers with a large number of microorganisms will cause contamination in food packaging containers, sealing machines and other links, causing too many microorganisms to adhere to the food. Resulting in unqualified food hygiene and safety quality.

In order to reduce the harm caused by workers’ hands to food hygiene and safety, food production and processing enterprises should establish a sanitation and sterilization procedure of “automatic hand washing → automatic drying → automatic disinfection and sterilization”, and actively use scientific GMP, SSOP, HACCP, QS quality management systems. . Small and medium-sized food processing companies install an automatic induction hand sterilizer in every major job position that needs to do hand disinfection and sterilization. While meeting the requirements of hygiene standards, it can also save disinfectant, improve work efficiency, and avoid disinfection and sterilization. The secondary pollution before and after can quickly sterilize the hands. Based on the time after hand disinfection and sterilization, it is recommended that the hands of workers engaged in food processing should be re-sterilized every 60 to 90 minutes.

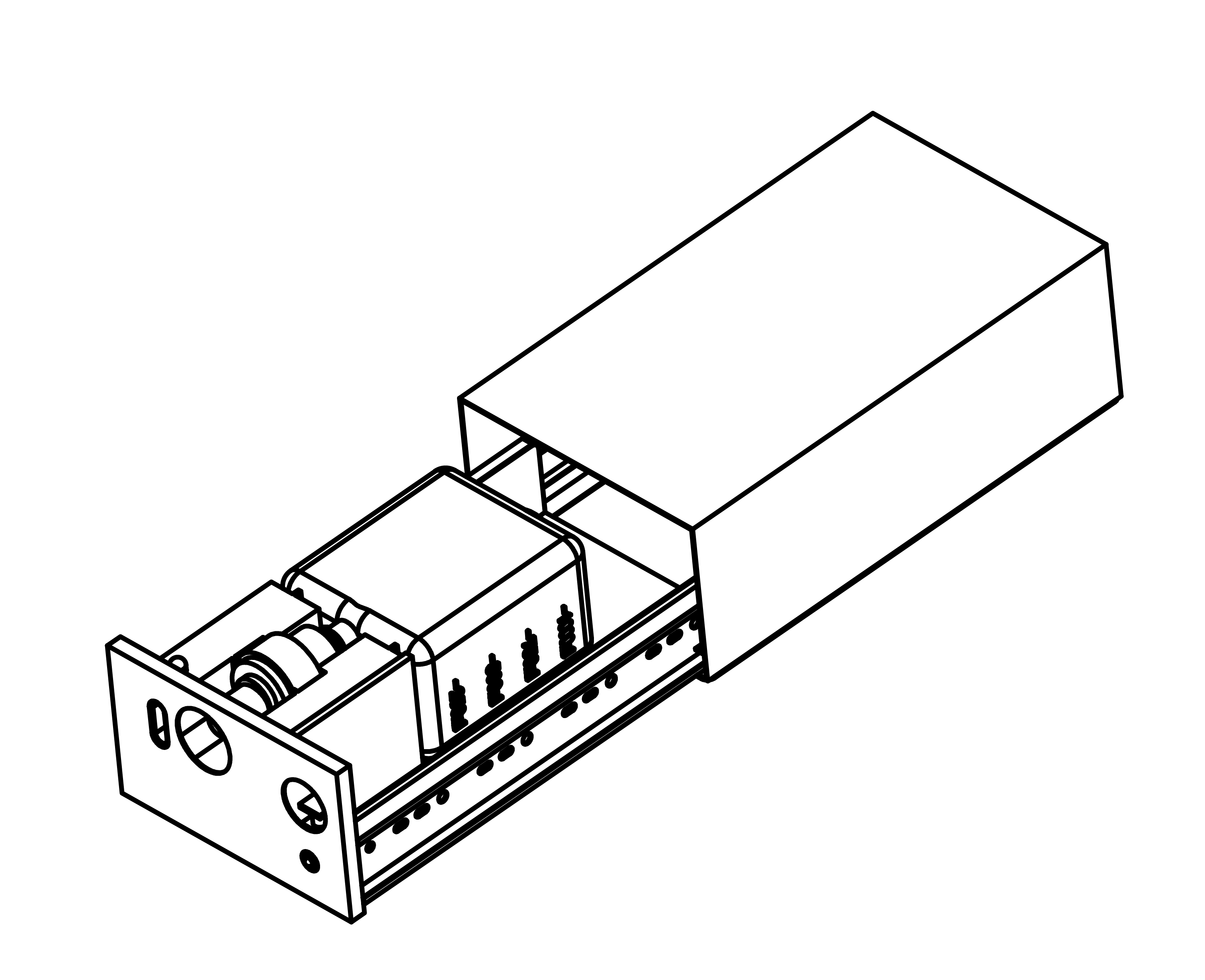

After installing the automatic induction hand sanitizer, if 75% alcohol is used as the disinfection and sterilization medium, the disinfection and sterilization process is as follows: handwashing by induction soap machine → faucet rinsing → induction drying → induction hand disinfection. After the alcohol evaporates, there is no residue on the hands.

In response to several food hygiene and safety issues such as hand microbial contamination, FEEGOO has successfully developed FG1598T automatic induction hand sanitizer” using the sterilization and disinfection technology selected by FEEGOO. It plays a very important role in creating a clean and hygienic production environment, reducing the microbial contamination of food caused by workers’ hands, and improving the efficiency of hand disinfection and sterilization. The application of automatic induction hand sterilizer and automatic induction hand disinfection technology can effectively improve the safety and quality of food, prolong the shelf life of food, and thus promote the healthy development of the food industry.

The technology of many small and medium-sized food processing enterprises is still relatively backward, and the processing technology and equipment need to be updated. Otherwise, these old and backward technologies and equipment will have a bad impact on the quality of food. In this case, ensuring the safety and quality of food has become a problem that needs to be solved. Small and medium-sized food processing enterprises should actively choose a complete set of food sterilization and disinfection solutions such as food sterilization and disinfection technology.

Post time: Feb-14-2022