1. According to the power supply method of the product: divided into AC hand sterilizer, DC hand sterilizer

In domestic AC hand sanitizers are usually powered by 220V/50hz power supply, the pressure generated by the electromagnetic pump is uniform, and the spray or atomization effect is stable, but the installation location needs to be equipped with a power supply

DC power supply usually uses power supply, and some transformers are used for power supply. Due to insufficient power supply capacity, the atomization effect of this type of sterilizer is usually very poor, and the effect is similar to that of a soap dispenser.

2. According to the state of the sprayed liquid: divided into atomizing hand sanitizer, spray hand sanitizer

Atomizing hand sanitizers usually use a high-pressure electromagnetic pump. The sprayed disinfectant is uniform and can fully contact the skin or rubber gloves. The disinfection effect can be achieved by using a small amount of disinfectant without rubbing. This product is becoming more and more popular. More and more mainstream products in the market

On the one hand, the pressure of the electromagnetic pump of the spray hand sterilizer is insufficient. On the other hand, due to the unreasonable design of the nozzle, the sprayed disinfectant has a flowing phenomenon, which leads to the unsatisfactory effect and the waste of the disinfectant, so that it becomes less and less. be chosen

3. According to the material classification of the sterilizer, it is divided into ABS plastic hand sterilizer and stainless steel hand sterilizer

With its stable chemical properties and easy molding characteristics, ABS has become an excellent material for the shell of hand sanitizers, but its color is aging and easily scratched, which affects its appearance.

Stainless steel hand sterilizers, usually made of 304 stainless steel, are durable and have become the best partner for high-end food and pharmaceutical manufacturers. .

The hands of food workers are most susceptible to contamination by pathogenic microorganisms. Some companies use peroxide-based disinfectants or chlorine-containing disinfectants to immerse their hands to disinfect their hands. Originally, they need to be soaked for 3 minutes to achieve the expected sterilization effect. Concentration, most of them can only symbolically share a pot of disinfection water for immersion, the disinfection time is not guaranteed, and many people reuse it, which eventually leads to the lack of disinfection water concentration and becomes a source of pollution. After washing hands, use a public towel to wipe hands, and the pollution is more serious. . Careless hand disinfection will not only contaminate food twice, but also contaminate containers, tools, work surfaces, etc., and finally superimpose cross-contaminated food, resulting in unqualified food.

Food processing enterprises are vigorously implementing “GMP”, “SSOP”, “HACCP”, and “QS” plans. If an automatic induction hand sanitizer is installed in each key position that requires hand disinfection, while meeting the standard requirements, It not only saves a lot of disinfectant, but also improves work efficiency, avoids secondary pollution before and after disinfection, and quickly kills bacteria on hands. Calculated by the time after the first sterilization, it is recommended to re-disinfect hands every 60-90 minutes to block bacteria on hands breeding and reproduction.

Then, how to choose a hand sanitizer has become a top priority for enterprises to establish a sanitation and disinfection program of “automatic hand washing and automatic disinfection”.

1. Fully consider your own situation and needs

Such as the number of employees in the enterprise, the number of channels entering the workshop, the economic affordability, and the purchase of hand sanitizers for both seat and hanging. What kind of disinfectant is planned to be matched. For example, 75% medical alcohol is used as the disinfection medium. The process is: “washing hands with soap machine – faucet flushing – induction drying – induction hand disinfection”; other disinfectants are used as disinfection medium The process is: “Induction washing hands with soap machine – faucet rinsing – induction hand disinfection – induction drying”; it is recommended to choose the first method, because there is no residue on the hands after the alcohol evaporates.

2. Comparison of single function and multi function

There are two types of hand sanitizers on the market: multi-function (disinfectant spray + hand drying) and single-function (disinfectant spray). On the surface, the former combines multiple functions to reduce equipment cost and compact working environment. However, placing the heat source of the hand dryer and the flammable disinfectant in the same body increases the risk of fire. At the same time, the compact working environment interferes with each other during work, and the probability of malfunction is high, thereby reducing the ergonomics, reducing the service life of the product and increasing the maintenance cost. Although the latter is a single function, the equipment cost is higher, but it ensures the safety of production, and also improves the use efficiency and reduces the maintenance cost.

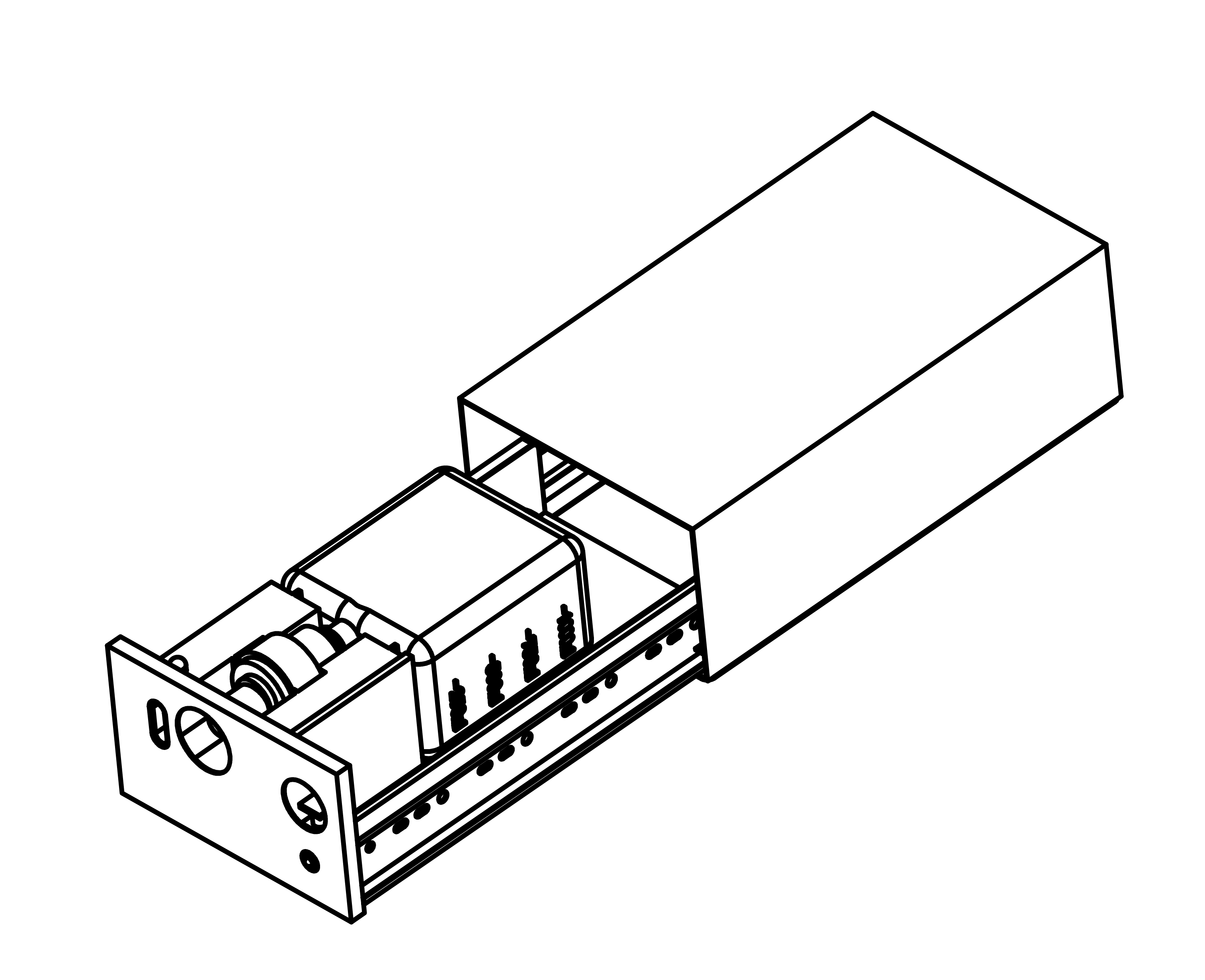

3. Understand the selection of “pump”, the key component of hand sanitizer

The pump is the key component of the hand sanitizer. The quality of the spray effect and the length of service life are all directly related to the type of pump selected. Hand sanitizers on the market generally choose two types of pumps, air pump and washing pump: the air pump is a high-power anti-corrosion pump, which can work continuously for 50 hours and has a design life of 500 hours. It is recommended for workplaces with more than 10 people. The hand sanitizer of this pump, the washing pump is a small pump. It is calculated as a working cycle of 5 seconds and 25 seconds of each work, and its design life is 25,000 times. Since the continuous working time of this pump is 5 seconds, if it exceeds this Time operation and high failure rate, so it is more suitable for workplaces with no more than 10 people.

4. Understand the protection technology of hand sanitizer pump

No matter how good the pump is, it can’t be de-liquid and idling. It is necessary to ask whether there is a pump protection technology. For example, when the added disinfectant is too full, whether there is a beeping alarm function; when the disinfectant liquid level is too low, whether there is a warning light flashing alternately to remind the function. ; When the disinfectant is left to 50ml, whether there is an automatic shutdown function; whether there is a voltage stabilization protection function when the current and voltage are suddenly large and small.

5. Overall performance comparison of hand sanitizers

Whether the hand sanitizer is made of stainless steel, because all disinfectants have a certain oxidative or corrosive effect on the surface of the object; whether the nozzle is a three-stage stainless steel bomb-type nozzle, and whether it can be replaced or taken out for backwashing when it is blocked, Whether the effect of the spray can be like fog, and the particles can be diffused; whether the hand sanitizer has a water discharge screw under it, which is easy to replace different disinfectants and easy to clean the liquid storage container; whether it has a recovery base and a sponge adsorption device, which can Prevent the disinfectant from falling to the ground.

6. Requirements for the variety of disinfectants.

Choose a hand sanitizer that is suitable for any brand of sanitizer, and there is no trouble for the user to bundle the hand sanitizer and the sanitizer. Users can choose disinfectant without any restrictions according to the company’s requirements for disinfection. At the same time, this choice will not exceed the conditions set by the supplier for the after-sales service of the product, and will not affect the after-sales service in the future.

7. Requirements for after-sales service.

Users must carefully understand the details of each manufacturer’s commitment to after-sales service, and try not to choose an enterprise that sets limits on after-sales service of its products or has no after-sales service at all, otherwise it will affect the normal operation of the user’s enterprise production.

Post time: Sep-22-2022